Sheet Metal Fabrication

Sheet metal fabrication is a subtractive manufacturing process that involves cutting, bending, and shaping thin metal sheets into precise components.

Sheet Cutting

Sheet cutting is a process used to cut flat metal sheets into specific shapes and sizes with high precision. It typically employs tools like laser cutters, plasma cutters, or waterjets, allowing for intricate patterns and consistent repeatability across production runs.

Laser Cutting

CNC laser cutting is a precision manufacturing process that uses a high-powered laser beam, to cut or engrave flat sheet materials. The laser melts, burns, or vaporizes the material along a programmed path, allowing for extremely accurate and intricate cuts with minimal material waste.

Laser Tube Cutting

Laser tube cutting is a CNC-controlled process where a high-powered laser precisely cuts through metal tubes. This allows for intricate designs, holes, slots, and complex geometries to be made on round, square, or custom-profile tubes with exceptional accuracy and minimal distortion.

Tube Bending

Tube bending is a mechanical forming process where metal tubes are bent to specific angles or curves without cutting or breaking the material. It’s typically done using CNC tube bending machines that apply pressure with dies and mandrels to maintain the structural integrity and inner diameter of the tube.

Die Casting

Die casting is a high-pressure manufacturing process used to produce metal parts by forcing molten metal into a steel mold, or die, under high pressure. The die is precision-machined to form the exact shape of the part and is typically made in two halves that are clamped together during casting.

Metal Stamping

Metal stamping is a manufacturing process that uses a die and a high-tonnage press to shape or cut metal sheets into specific parts. It includes operations like punching, blanking, bending, and embossing, and is widely used for producing high-volume, consistent components with tight tolerances.

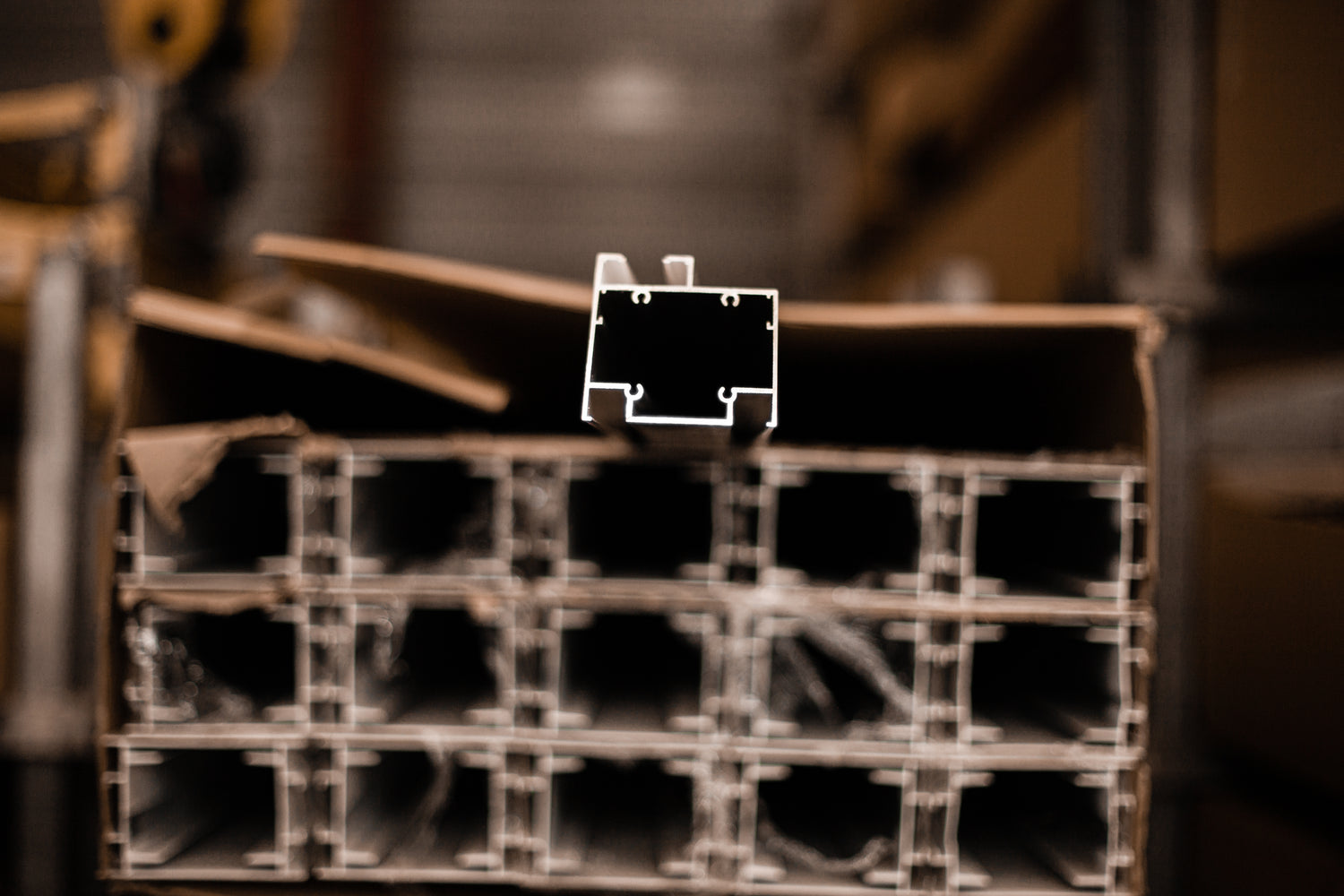

Metal Extrusion

Metal extrusion is a manufacturing process where a metal billet is forced through a die to create long objects with a fixed cross-sectional profile, such as rods, tubes, or channels. The process can be done hot or cold, depending on the material, and is commonly used with aluminum, copper, and steel to produce lightweight, strong, and uniform components.